If you're looking for one of the fastest methods for producing metal stampings, look to progressive stamping. In progressive stamping, a steel coil moves through a feed in the press and gets stamped by multiple operations in timed sequences as it moves through the press, resulting in final parts.

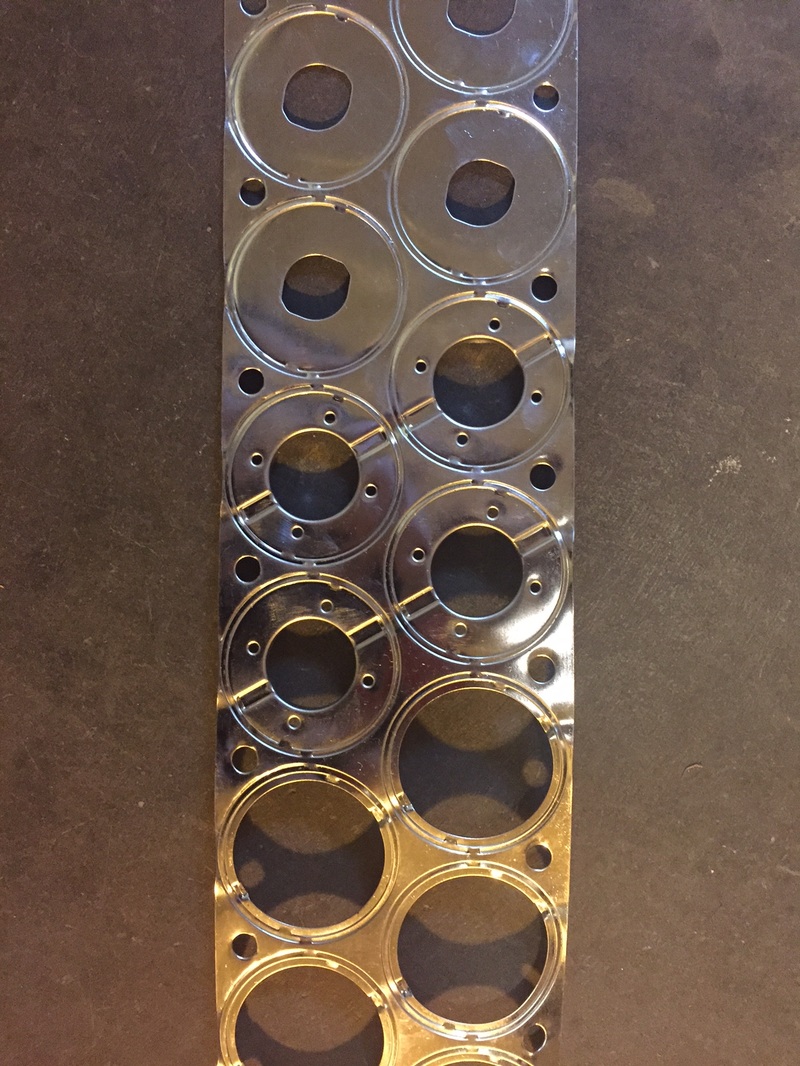

We at Donahue Industries in Massachusetts use progressive stamping to metal stamp thousands of grinding wheel inserts.

We at Donahue Industries in Massachusetts use progressive stamping to metal stamp thousands of grinding wheel inserts.

Progressive dies can produce as few as seven or eight parts per minute or as many as 1,500 parts per minute.... All necessary stations are mounted on a single common die set. These stations are timed and sequenced so that the piece part can be fed ahead a constant given distance called the progression or pitch. Many parts can be tied together allowing many parts to be made with each single press stroke.

Art Hedrick of The Fabricator

RSS Feed

RSS Feed