Use a wire rope sheave gauge only to APPROXIMATE wire rope diameter:

- Place the wire rope in the proper size gauge. Make sure the wire rope is oriented properly, from the top of one strand to the top of the directly opposite strand.

- If the wire rope does not fit in the gauge, repeat with a larger size gauge until the wire rope fits in the gauge.

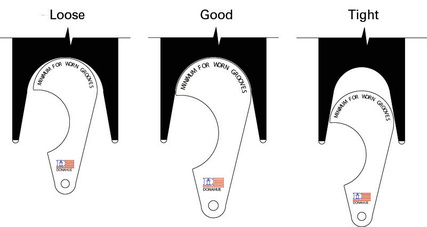

- Shine a light behind the gauge.

- Check for light between the gauge and the wire rope. If you detect light, repeat with a smaller size gauge until no light shows between the wire rope and the gauge.

RSS Feed

RSS Feed