How To Use A Sheave Gauge

Why Maintain A Sheave

Maintaining a wire rope sheave is much more cost-effective than replacing wire rope. To maximize the life of the wire rope, re-tool or replace a sheave when grooves become:

Maintaining a wire rope sheave is much more cost-effective than replacing wire rope. To maximize the life of the wire rope, re-tool or replace a sheave when grooves become:

- So worn that they allow for excessive wire rope movement OR

- So small that they twist and compress the wire rope.

|

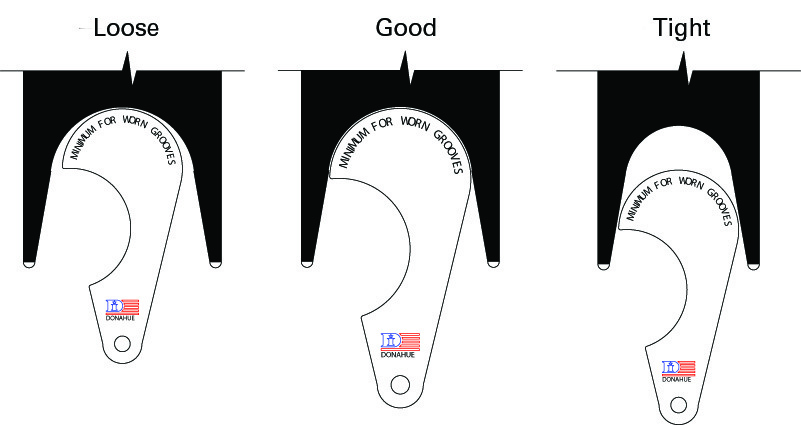

How To Determine The Amount of Wear Using A Wire Rope Sheave Gauge

Use a wire rope sheave gauge to regularly check sheave grooves for wear, which may slow or block a wire rope:

|

|

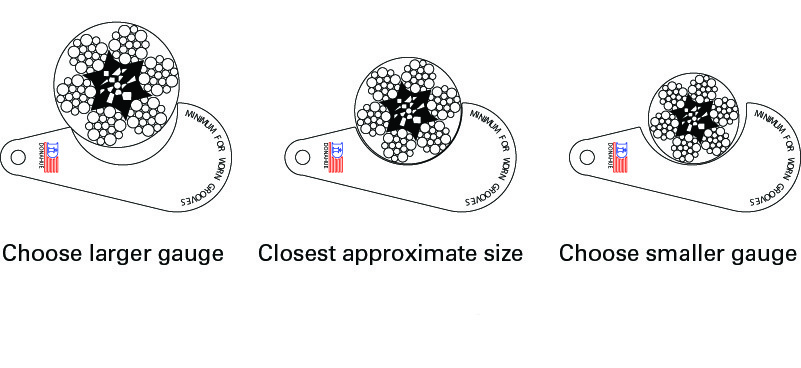

How To Approximate Wire Rope Size

Use a wire rope sheave gauge only to APPROXIMATE wire rope diameter:

|

|

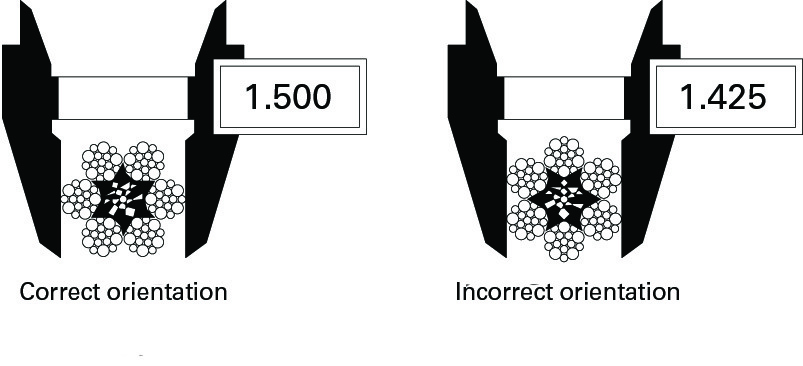

How To Accurately Measure Wire Rope Wear

For an ACCURATE wire rope diameter measurement to determine if you should retire the wire rope, use a machinist’s caliper or micrometer. To properly use a caliper to assure accurate measurement:

|

More Information on Wire Rope Measuring Techniques

American Society of Mechanical Engineers

American Society of Mechanical Engineers